|

|

Planlegger du å lage en slik båt selv, fra bunn av - Eller som

under her som et byggesett - burde du ha god tid - Faktisk

veldig god tid - se under her - over 1300 timer ....

Legg

også merke til prisen på byggesettet : £700 er ca 6300 Norske

kroner ... |

|

Building

The Jotika HMS Victory

At near

enough £700 this kit is a large investment but there is

several years work in it so across time it is a very cheap

way of spending your time. A friend of mine name of Brian,

asked if I could get him the HMS Victory kit when it came

out. Brian had just finished his first rigged ship model

and as luck would have it annual bonus payments made it a

possibility. As always there was a slight snag - due to

ever increasing research and information this kit has been

a couple of years in the making and, on Bonus day, it

still had not been issued, so we waited. Then waited some

more. Finally the announcement came and went - and in due

course the kit arrived.

We had

arranged to meet and swap the kit over in Bristol - but

when I tried to move it - it quickly became apparent that

that was not a real option. So Brian arranged to come and

collect it. Why? well the box is near 4 feet long by 1

foot square, and it is full to the brim with wood and

metal parts. Any way Brian took the kit home and started

to build. Hopefully we will follow the build on the site

with a few pictures as we go along - and get the tru story

behind building the kit.

The frst

comment is that with the copious plans, build instructions

and parts, and even at £700 this kit looks and feels like

good value for money!! First is the keel and frames and

then the first layer of planking. The planks are long and

some require a fairly severe bend in them so they were

soaked in hot water to make them plyable before shaping

and fixing. Very straight forward except the only

container large enogh was the bath! I think Brian has now

invested in a plastic pipe. Any way he said that the build

to and including the first layer of planking was straight

forward but could only proceed relatively slowly - 4

planks an evening. He has also been looking at the

remaining build trying to figure how he can interleave

some of the more repetetive work (building canons) with

the more interesting stuff!

Picture

1 - up to first planking!

|

64

hours - Starting the rear galleries

The

rear gallery has been started - as with all things

at this stage it looks very messy, filling sanding

and painting to do, so any errors will be covered

up. The main hull of course has another layer of

planks, and a layer of copper plates on most of it

(paint on the rest) which will cover a multitude

of sins - but you still need to take care as you

will always know that they are there!!

The

nine forward facing windows in the quarter gallery

are glazed, but it doesn't really show in this

photo. The gallery is made of 3 ply, so the grain

direction is quite critical. Bending parallel to

the grain is easy, bending across the grain is

almost impossible. The six layers in the quater

gallery are alternating grain directions, so it is

quite a job getting them aligned....

|

73

hours

This

is the middle deck planking. The lower gun deck is

not visible at all and this deck is actually only

visible at the bottom of a few stairwells. As most

of this decking will not be seen, its a good

opportunity to practice and perfect the techniques

- felt pen around the edges of each plank is too

thick and smudgy so I will not attempt this method

again (I'll try the black paper method).

The next photo (when I've taken it) will show the

second hull planking progressing. I'm Currently on

the 45th plank (90th if you count both sides!!),

but there are about another about another 20 to go....

|

117

hours

The

second planking to the lower half of the hull is

finished. The rear half of the keel and the stern

post is finally glued on. With all the shaping and

sanding I was worried they would not fit, but it

was not too bad in the end. All of this nice

planking will be painted or buried under copper

plates, but after filling and sanding it will not

look so nice anyway!

|

126

hours

The

camber beams to support the upper gun deck are now

in place. One last chance to look at the middle

gun deck planking as virtually none of this is

visible after the upper gun deck is in place

|

128

hours

The

upper gun deck and the inner bulwark patters are

in place. Although you can still see the middle

gun deck, the grating will cover most of these

holes. Quite a bit of shaping is required to

ensure the inner and outer gun ports line up.

|

140

hours

The

upper gun deck and inner bulwarks are planked

(still using the felt pen method as a) I’m

getting better at it and b) most of this deck is

also hidden. The inner bulwarks will be painted

yellow ochre but I’m still deciding on the best

shade to do. The recommended colour is very pale

and washed out. Do I go for authenticity or

something that looks more dramatic/pretty? (the

latter I suspect).

|

165

hours

165

hours into the project and 16 of the gun ports are

lined - very fiddly indeed, and these are the easy

ones with inner and outer plates to glue onto -

just wait until I get to the lower ones, where the

lining is glued to just one 1mm edge.

|

173hours

173

hours and the wales are in place. They are a bit

difficult to see in this photo, but look for the

planks that go at a different angle to the main

area (bending up towards the stern). Lots of

filling and sanding done, so things looking a

little tatty. I’ve just started the main lot of

gun port linings - 72 to do, that’s nearly 300

fiddly bits of wood to glue on (the next photo may

be some time away….)

|

191

hours

Happy

Christmas / Happy New Year - and another picture!!

Gun

port linings finished much sooner than I was

expecting (18 hours work). 72 gun ports lined in

all (4 per hour). After a while it becomes easy.

Initial fears of balancing a thin sliver of wood

on a 1mm vertical edge soon faded when I

discovered the three tricks - cut the wood a tiny

fraction too big and then you can wedge it into

position. Don’t use superglue, as you need to

adjust each piece to ensure they are sunk in to

the right depth and run parallel around all sides.

Do the two vertical edges, let the glue dry, then

do the top and bottom. If you try to do all sides

at once while the glue is still wet, you end up

knocking bits out of position (I still ended up

with quite a few parts that dropped inside the

hull never to see the light of day again…)

|

222-269

hours

222

hours, (31 hours of painting later), the Victory

looks quite colourful. Me and masking tape don’t

get on well and in the end all the painting was

done freehand. A wee bit wobbly in places but they

didn’t have masking tape in Nelson’s day after

all. The yellow I chose was a little deeper than

that recommended, but I took a bit of artistic

licence…

Another

36 hours on (258 hours into the build) and the two

and a half thousand copper plates are in place.

Just like laying bricks. A few tips (the second

side when on much easier than the first noting

these) – When gluing the first row take extra

care to line then up perfectly – subsequent

layers will line up much easier. If you make a

mistake and stick one on slightly out of place –

rip it off, it’s very difficult to work around a

wonky one (don't do this too many times though,

I'm not sure how many spare plates there are - I

still have to do the rudder)

269

(and a half) hours in, and some detailed work at

last. Gratings and stairways, plus loads and loads

of little canon balls. Most of this upper gun deck

will be covered by the quarterdeck, but this deck

will be far more visible than the poor middle gun

deck (you can just see a bit at the bottom of the

stairway, lower left of the photo. The loose

threads are the companionway guard rails and will

be fixed to stanchions and pillars at a much later

date. Next job is the 30 canons on the upper gun

deck...

316

hours (47 hours since the last photo) and all 30

of the upper gun deck canons are complete. Each

one is built in 18 stages over eight days, so

quite a lengthy conveyer belt going most of the

time. Lots of tiny pieces (especially those little

rings) so heavy use was made of the old magnifying

glass. Next set of work is rigging the canons –

more work under a magnifying glass, and my fingers

are just that little bit too big. I’ve decided

that the rigging is so fiddly, I will not be doing

the canons that are completely hidden under the

quarter deck (about half of them)

|

|

|

347

hours

347

hours in, now passed the six months elapsed time (7

months 25 days). The cannons on the upper gun deck

are finished and I think I could make one

blindfolded. Four additional stages to the rigging

meant an elapsed time of 12 days to make a cannon (had

I done all 30, one at a time, it would have taken a

year!). Rigging was a bit fiddly, but got the hang

of it near the end – hopefully the quarterdeck

cannons will be neater. I only rigged 14 in the end,

as the other 16 are well and truly hidden. Now its

on with more pillars and stairs up to the

quarterdeck…

|

361

hours

8

months (less one day) elapsed, and 361 hours in. The

quarterdeck is on, and having spent just over 100

hours on the upper gun deck, this is all you can see!!

What makes matters worse is that later on (next year

probably), the four ship’s boats will be placed on

top of this area. Still, I know all the detail is

there, and the ship’s boats will cover up some of

my awful knot tying (I must get a book or something

to help). The stairway rigging and pillars all had

to be done after the skid beams were put on. This

makes it a bit like keyhole surgery, and most of

this work has to be done with tweezers. There were a

couple of heart stopping moments when I dropped two

of the pillars – yes, they bounced down the

stairways into the middle gun deck. I managed to get

one back up the stairs and the other out through a

gun port (phew)

|

421

hours.

At

last, all the outer hull planking is on and painted.

The inner lining and gun ports are also finished

apart from the poop deck. This is now the start of

the sticky-up bits on the deck such as the galley

stove chimney – they all look very nice but will

be prone to knocks (fingers crossed!)

|

438

hours.

More

sticky-up bits to accidentally knock off. The belfry,

the quarterdeck barricade, waist ladders down to the

gun deck, the main companionway staircase and

balusters and the companionway to the admirals

dining cabin are now in place. One calamity occurred

doing this. The main companionway ladder is the only

one without rope handrails, which are very handy for

lowering the ladders into place. This last ladder is

the only one that is fully visible and I dropped it

into the stair well. Not only did it slip down to

the upper gun deck, but it also slid down the next

staircase to the middle gun deck – completely out

of reach and in total darkness. D’oh! As Homer

would say. After much fiddling with tweezers and a

torch, I had to bight the bullet and remove the

other ladder to the middle gun deck so I could

retrieve the missing ladder (successfully) .

I also tripped over and nearly dropped the model, so

I’m stopping for today…

|

498

hours.

things

are starting to look pretty at last. 14 more cannons

completed and I’m finally getting the hang of the

rigging. I used a little jig rather than tying all

the lines in situ – a vast improvement. The

screens behind the wheel maybe should have been just

plain wood finish (as on the current Victory décor),

but I couldn’t resist the yellow and black

panelling (as in the old Victory guide books), which

I think looks so much more interesting (if less

historically accurate). The windows are glazed but

it doesn’t show up in the photo. Next photo (in a

week or so) will be the beakhead which is nearing

the completion of the first stage (blue paint make

such a change from yellow and black)

|

518

hours

(I’ve

past the historic 500 hour mark) and the beakhead is

started. Relatively simple stage (especially

compared to the next bit). My first taste of gun

port lids, not too bad but still around a hundred

left to do. Bending the mouldings to fit around the

roundhouses was a bit tricky, but nothing that a

little trial and error wouldn’t cure. The two

large cannons were the very last two to be done. You

can just see the ship’s bell at the top of the

picture.

|

560

hours

.....

and the bow is just about finished (just a little

touching up here and there). Lots of curvy bits that

were very tricky to line up – all the curves are

three dimensional so while it’s easy to align

things up-down and left-right, you have to keep

checking the in-out curve as well. Not too many

photos showing how the bows should look and they all

seem to differ a little, but hopefully it’s about

right. Notice there are lots of sticking-out bits

now (the yellow cat-heads and the black boomkins)

– great care will be needed taking the model in

and out of the cabinet now! (yes, I’ve knocked one

already). The figurehead was hard on the eyes – I

needed a very large magnifying glass and a very very

small brush (00). The actual figurehead has huge

amounts of detail that is just not possible in a

casting this size, so some “approximation” has

to be done. From a distance however, it does not

look too bad.

|

594

hours

.......

and more importantly, I’ve just past the first

anniversary of starting – its been one year and

three days since I glued the keel together. The poop

deck is just about finished, the deck planking went

really well and looks much better than previous

attempts. Unfortunately, looking much better means

it does not match the other decks so well – D’oh!

Lots of fiddly work on the poop deck – 52 little

windows in the skylight and 21 little buckets to fix

handles to.

Next step – the stern – lots more detailed

painting – time to get a new brush and visit the

opticians…

|

630

hours

..

and the stern gallery is nearly finished. This stage

was probably the most satisfying so far. Although it

looks very fiddly to do it was not too bad. The

etched brass fittings are very detailed and because

they can be all painted separately there is very

little to paint in situ. The most difficult bit was

actually mitring the brass mouldings that go around

the base, which has to be bent and bowed in all

sorts of directions. These moulding have to be

joined at a little less than 90 degrees, and the

whole thing slopes backwards as well. Good old

milliput filled the gaps though! The crisp finish to

the castings helps with the painting as well and I

think the end result looks rather good (if I do say

so myself). I’m still looking for a good reference

picture of the stern trophy of arms before painting,

I may go down to Portsmouth soon….

|

|

On

Quite another tack - Dave Bevan has told us of his

efforts with another makers kit and particularly the

copper plateing. After trying for some time with the

supplied plates he saw some copper tape for sale in

varying sizes. The tape and some wheels from a cheap

Argos alarm clock have proved to give him the answer

to the plates and the nail impressions. Dave did

supply pictures but some cameras just cannot cope

with real close up work and they were a bit blurred

to reproduce. Thanks Dave and perhaps we can have a

picture of the whole model sometime.

|

|

690

hours

I

finally visited the Victory at Portsmouth to get

some photos. There was scaffolding and plastic

sheeting over the stern, but luckily the trophy of

arms was still visible. The 105 photos I took was

probably a little bit over the top, but the trophy

of arms at the stern is now in place (690 hours

into the build). I’ve also started the channels,

gun hatch lids and mouldings (the blurry bits to

the right). A new (sharper) photo will be posted

soon (of the full side view).

|

716

hours

This

stage should be channels, and then gun hatches,

followed by the mouldings but I found it easier to

do all three at once, as hinted at in the

instructions. After 72 hours (two months) I’ve

done about 1/2 of the work (one side), so at this

rate I won’t start the rudder until the New Year.

This part is very fiddly (especially the chain

plates) but the end result is very effective, with

so much fine detail. Photos are a bit of a problem

as most of the detail is black on black. I’ve

temporarily removed the boomkins in the bow (see

560 hour photo), as they were rather delicate And

no matter how careful I was taking the Victory in

and out of the display case, they kept hitting the

sides and one even snapped in half (nothing a bit

of super glue couldn’t fix). I’m not even

thinking about putting the stern lanterns on until

I get a bigger display case (if I ever find one

that’s 5 foot wide!!)

|

779

hours

The

second side of gun port lids, channels and chain

plates and mouldings are all finished. The rudder

is also in place and I was very pleased to find I

had enough copper plates! It only took me ten

hours of work after finishing all the gun port

lids before I knocked one out of position. It only

bent a bit, as they are all secured with two brass

rods but the ropes had to be re-done. I guess this

won’t be the last one.

|

811

hours....

.......and

I’ve reached the momentous position of having

finished the first part of the construction - the

first of the two instruction manuals. The hull is

completely done, and it’s on with the masts next.

The final part of the construction was all the

ropes across the hammock cranes, handrails, and

the poop deck barricade (plus the four anchors

which are attached much later). Actually, I’ve

started the ship’s boats next, as they will fit

in the display case – unlike the masts!!

|

896

hours....

The

instructions say the ship’s boats will take

about two weeks of evening work. Well, I guess I

must be a bit slow as it took me about 85 hours (that’s

about 6 hours per evening over two weeks) It

actually took just over two months, but it was fun.

Each boat is a little miniature double planked

creation. Apart from the size, the main difference

between them and the full sized ship is that the

bulkheads have to be removed and your handiwork is

“exposed” on the inside. The instructions show

the boats with just a few oars inside, then they

tell you they actually had 4, 8, 14 and 16 oars

altogether so it ends up looking very crowded. I

think I could have arranged them a little better

though. You need to make sure make sure you keep

the planks tight into the bulkheads as there is a

tendency for them to splay out a little. The boats

are a very tight fit when placed in position, with

less than a millimetre to spare, so it’s no good

having them too big.

There is disappointingly little of the upper gun

deck visible once the boats are in place - perhaps

I’ll do a diorama with the boats at sea! Plenty

of time to make up my mind - they don't get

secured in place until after the rigging (a very

long time away!)

|

910

hours

The

masts are started (well the bowsprit anyway). I

think this is the first time when carpentry skills

(or lack of them) become more important than model

making skills. The angled joint to fit the cap on

was a real challenge and I got it perfect first

time – just a pity it was a mirror image of what

it should have been. The second attempt was not

quite so good unfortunately, but I couldn’t face

making a third one and it was to be painted black

anyway. It became obvious during the bowsprit

construction that just sanding and filing would

not be good enough and a lathe was going to be

worth investing in. I’ve now got a miniature one

for doing all the masts and yards and it’s so

much easier (although lathing an 8” length of

6mm dowel down to 2mm one end is a bit hair

raising!). ( you can do this in an electric drill

- it's what I used for a number of years. Allan)

|

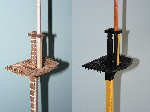

937

hours

I’m

nearly finished on the foremast. The photo shows

two stages, the one after painting is difficult to

photograph (all the detail being black), and so

the left hand one is before painting. I chose to

do the banding in plastic-card rather than paper.

The card is stronger and (more importantly) comes

pre cut in perfect strips (Ok, cheating a bit). If

you’re making the Victory, and haven’t got to

this stage yet, I found the topmast caps (fore and

main) needed splitting to fit over the topmasts (the

mizzen topmast cap comes pre split). The caps

split very easily as they are solid wood not ply.

They glue back together again with no join showing

at all.

|

1000

hours

At

11:00am on Saturday the 25th June I completed my

1,000th hour on the Victory, nearly 2 years after

starting – quite a moment. The picture here

shows progress at around 990 hours (I’ve started

on the yards since then). The masts are just

placed in their holes, so not fully aligned in the

photo. With the masts in place, the scale and size

of the ship really comes home and I realise

carrying it to and from a cabinet for the final

stages of the build will be fun – you have to

bend quite low to get under the door frame for

example! Guess I will have to think about a

dedicated room (I’m sure my wife would like to

get me out of the kitchen!!)

|

1044

hours

,

and I’m putting the finishing touches to the

yards. This is the main yard and is surprisingly

complex to make – there are some 69 parts making

up just this one yard – not including all the

threads. The lathe has proved invaluable.

|

1054

hours

I’ve

finished all the yards. Here they are, laid out in

all their glory, alongside the masts, bowsprit,

booms, gaff and other nautical bits and bobs. The

next step is the glue the masts in place. Oh dear,

now I really will have to look for a new home for

the Victory, as it’s about to outgrow its

current display case...

|

1055

hours

Work

has finally started again. After the long delay

looking for a new cabinet to keep the Victory in (the

old one wasn’t big enough for the masts) I built

one. A 5 sided glass case will be the final choice,

but totally impractical during the build phase.

Display cabinets were too expensive, so I’ve

gone for a temporary DIY job – Four bits of

contiboard, a big bit of hardboard, and three

pieces of Perspex to keep the dust out. Its nearly

5 foot by 4 foot by 2 foot – a bit unwieldy

getting it up the stairs, but I now have a Victory

room (or is it the Trafalgar room?) to work in.

The masts are glued in place and I’m now adding

the pendants. Next photo will be the start of the

shrouds…

|

1065

hours

....

another momentous point - the start of the rigging

- first two shrouds in place on the foremast -

quite tricky, as there are so many things to catch

your fingers on - better get used to it though. I

used a jig (of bent brass wire) to get the spacing

right between the dead-eyes - much easier now.

|

1111

hours

I’m

well into the rigging. The shrouds are almost

finished, and this shot shows the main mast lower

shrouds, lower futtock shrouds, carthapins,

topmast shrouds, lanyards etc. If you’re making

this model (and haven’t got to this bit yet) pay

attention to the instructions for the carthapins

(I didn’t, and they are not quite right – they

shouldn’t all line up with the futtock shrouds.

Its quite tricky getting all the tensions to all

balance up, but the secret seems to be - don’t

over tighten any of the ropes. I did over tighten

one, and the deadeye snapped off and shot across

the room into the landing (the rest were a lot

better!)

|

1120

hours

1120

hours and all the shrouds are done. Next it’s on

to the ratlines. Several thousand knots to do and

my eyes and fingers will only allow about one hour

at a time (about 100 knots). The picture shows

work-in-progress – the loose ends are trimmed

when the glue has dried

|

1126

hours

Not

long since the last update. This photo shows one

side of one mast. The biggest problem is avoiding

the rest of the model while my fingers are

concentrating on tying the knots. A few close

encounters with the gun ports and fences, but no

serious damage. I’ve made a little ruler showing

the distance between ratlines on a piece of

plastic-card – essential when gauging the last

six ratlines which have to be shorter than the

rest. I’m currently at 1148 hours (but the

rigging is just more of the same) – Next photo

will be when all the ratlines are done –

hopefully before Christmas (I'm around 5/6 of the

way through)

|

|

1153

hours

..................and

as predicted, I’ve finished the ratlines before

Christmas (on Christmas Eve!). It only took just

over 37 hours, which for 2,777 knots is around 74

per hour. The more observant of you will notice

2,777 knots does not divide by 2. Either I’ve

miscounted, or the port side does not match the

starboard (I suspect the latter). Looking forward

now to adding the bowsprit – although once added,

the model will be much less easy to move in and

out of the cabinet…

|

1172

hours

–

about 20 hours work over the Christmas holiday.

The bowsprit is on, the mizzen mast stays are done

and the fiddliest bit – the main stay, complete

with snaking was finished tonight (the end of the

holiday). Tying the snaking onto the main stays,

in-between the foremast shrouds was very fiddly

– my hands are too big! The hardest part of the

rigging seems to be avoiding hitting other bits

off the model – the jack staff was the main

casualty today – I knocked it off twice (I’m

leaving it off for a while now...)

|

1195

hours

...

and well into the stays. Photo shows the stays and

preventer stays going from mast to mast and the

backstays going from the masts to the channels at

the base of the shrouds. It’s starting to get a

bit like a spider’s web. Had another major

catastrophe during this stage – snapped the end

of the bowsprit off while moving the ship around

to get to the other side. Managed to repair the

damage without needing to go back and replace/redo

bits (hope it holds). Many people have already

asked to see the photo of the damage – and the

answer was no, I didn’t take a photo...

|

1211

hours

All

the stays are finished (and no more casualties!).

I’ve just started putting the first of the yards

on – these will make the model a lot deeper and

hence harder to move around (... I'm preparing for

another calamity). The next photo will however,

start to look close to the final thing…

|

1223

hours

......

and the first set of yards is in place on the

foremast. I have now actually fitted all nine

yards, but until the next stage of the rigging,

many of them hang at odd angles and look somewhat

silly (hence no photo for that stage!). The more

observant among you will notice the lack of the

jack staff. It made a brief appearance in the last

photo, but got knocked off yet again and lost in

the dark recesses of the Victory room. Making a

new one will be easy, but I really am going to

delay the fitting until the last possible moment

this time!

|

1256

hours

(Sorry

- I have been very tardy in putting this update

from Brian up. )

More and more and more threads. All the yards are

in place, and held by the lifts (diagonal threads).

It is getting more and more difficult to get to

various pats of the ship to do the rigging (eg the

base of the mast) and I am only about half way

through the rigging - I'll have to go on a diet to

get my fingers thinner. Two pairs of tweezers are

essential, as are very slow movements...(So time

to introduce the push and pull hooks. I used to

use these when I worked on adding machines in

order to pet springs in place. We used to make

them from silver steel ground to a long point then

bent carefully bent into a hook shape for pulling

with or a half hook and then bent back on itself

so that there is a dip for pushing with. Then heat

to red and quench with water to harden. Clean it

up and heat again away from the tip until the

colour runs down and the tip is light straw going

to blue - then quench - this makes it springy. You

can just about make something out of brass wire

but not terribly good though effective)

1294

hours

and

the stern is complete. In fact I realise that

there are only three more pages left in the

instruction manual and the whole project is only

weeks (if not days) away from being finished –

scary! Only a couple of major calamites in this

session, including a snapped piece of rigging (after

I accidentally knocked the main yard). It was a

very odd breakage, much of the rigging went slack

and it took me several minutes of puzzlement

before I spotted the offending break. Luckily it

was in an accessible area and repair was quite

easy (phew)

|

1321

hours

On

Sunday April 30th 2006, at 8:35am I glued on the

jack staff again (for about the fourth time). That

was it, the final piece – HMS Victory is

finished ! 1321 hours in total, spread over 2

years, 8 months and 25 days – that’s 999 days

(I should have stretched it out for one more day!).

I have to say a big thank-you to JoTiKa for making

an absolutely fantastic kit, which was a joy to

make (all 79,260 minutes of it ....or 55 days 4

hours accumulated work ...ed). Also, thanks to

Allan for posting the photos here, and my wife for

putting up with the mess ! Now what will my next

ship model be?……Brian - it has been an

absolute pleasure - we would love to follow your

next build

|

|

|

|

Alle

bilder på disse sider er beskyttet ihht. opphavrett.

|

|

|

| Noen

av de andre båtene og skipene : |

|

INSPIRASJON :

Under er noen tilbakemeldinger fra våre kunder, som har bygget om

våre modeller, bl.a. til fjernstyring med elektromotor og til og

med live steam. |

SNEKKE

MED ELEKTROMOTOR OG RC

|

SNEKKE

MED DAMPKJELE OG RC - LIVE STEAM

|

KNBF

overrekker snekke til Draugen Motorbåtforening i

forbindelse med 80 års jubileum.

|

|

|

|

|

|

|

|

|

|